Magnetic Shield Fabrication and Prototyping

Fabrication Services

Magnetic Shield Corporation designs, prototypes and manufactures magnetic shields for thousands of customers worldwide. With a full range of stock shielding materials, in-house equipment, and on-site skilled welders and fabricators, we are able to produce one-off samples, small production lots, large production batches and annual volumes.

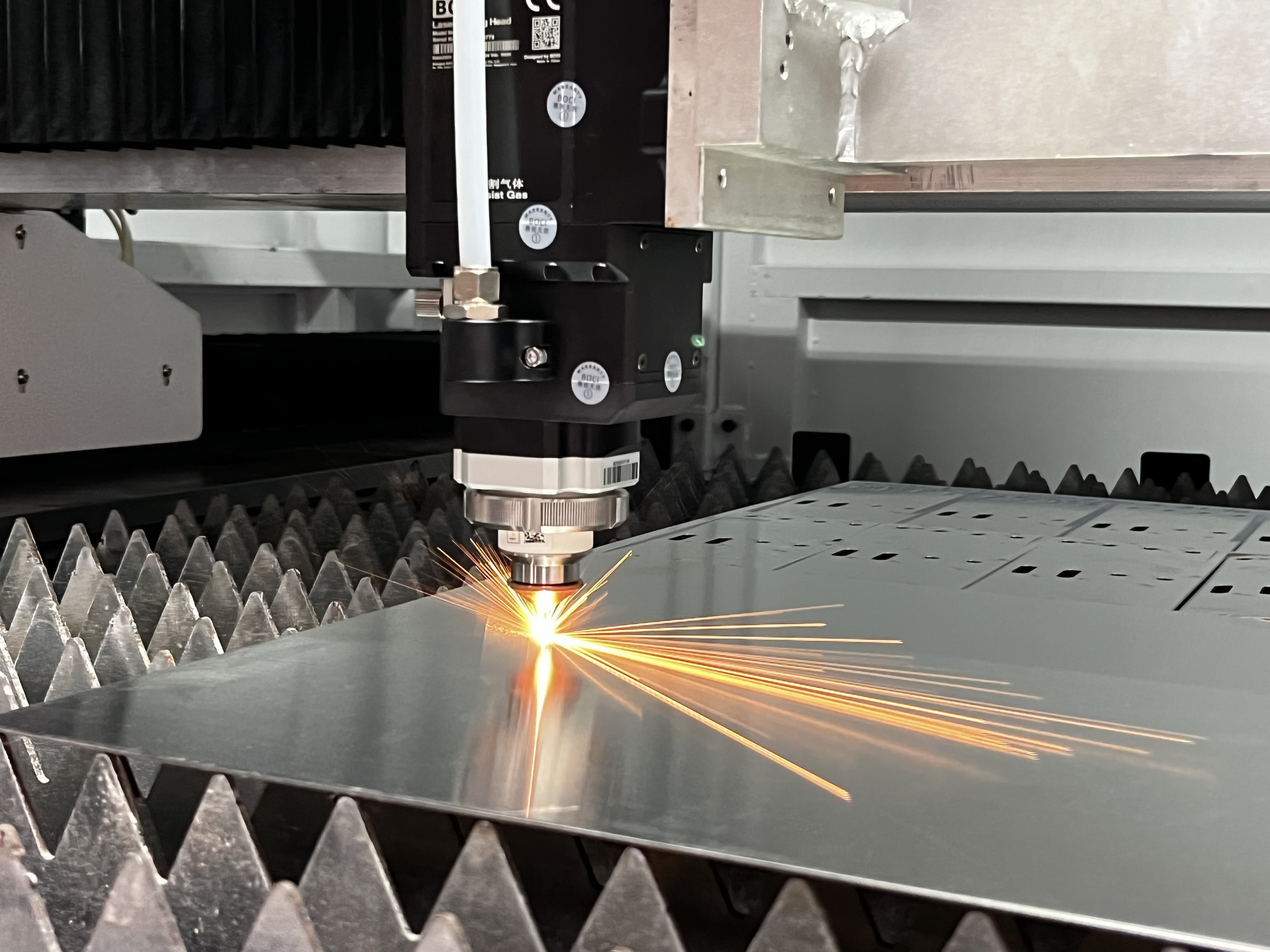

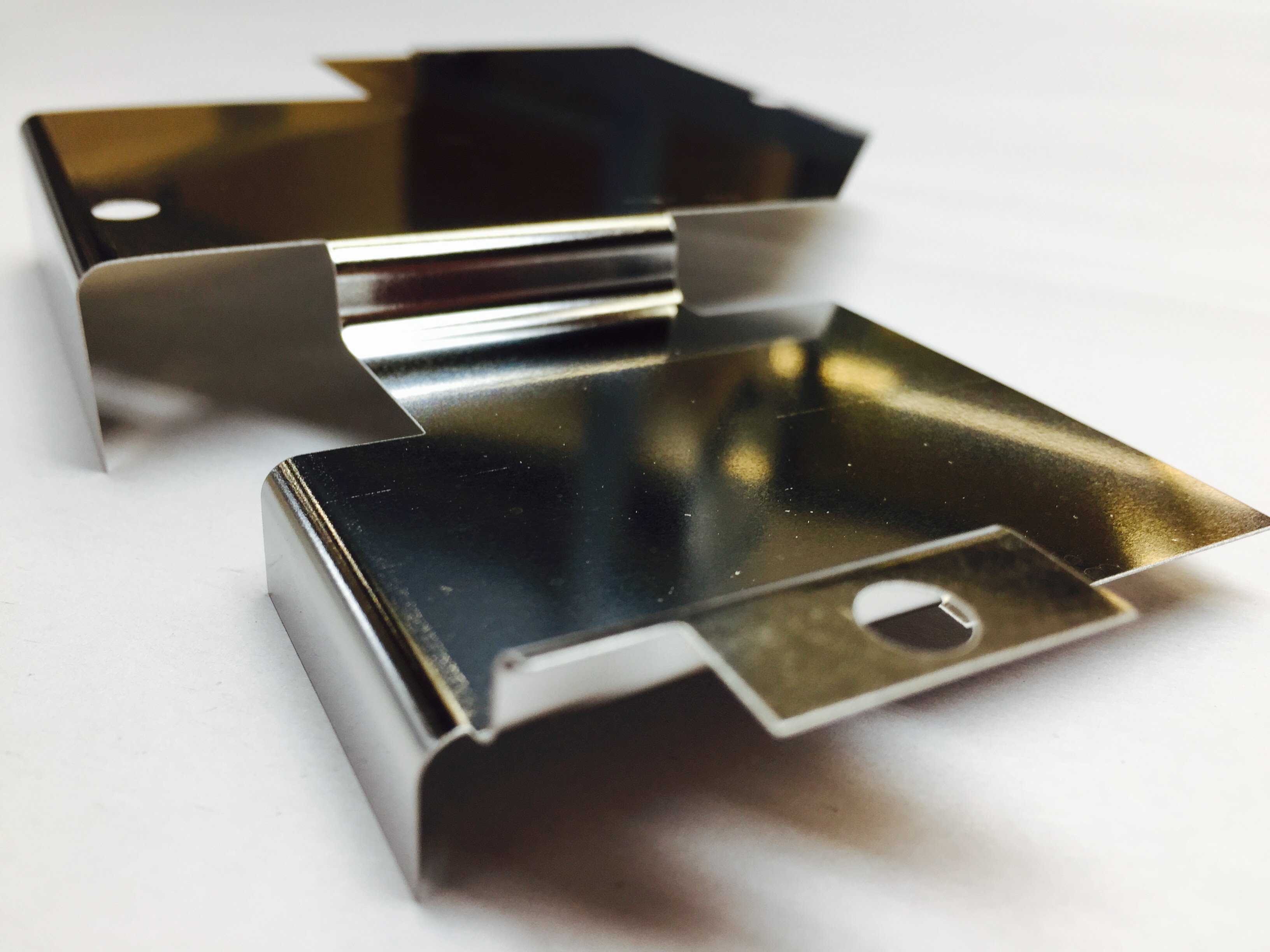

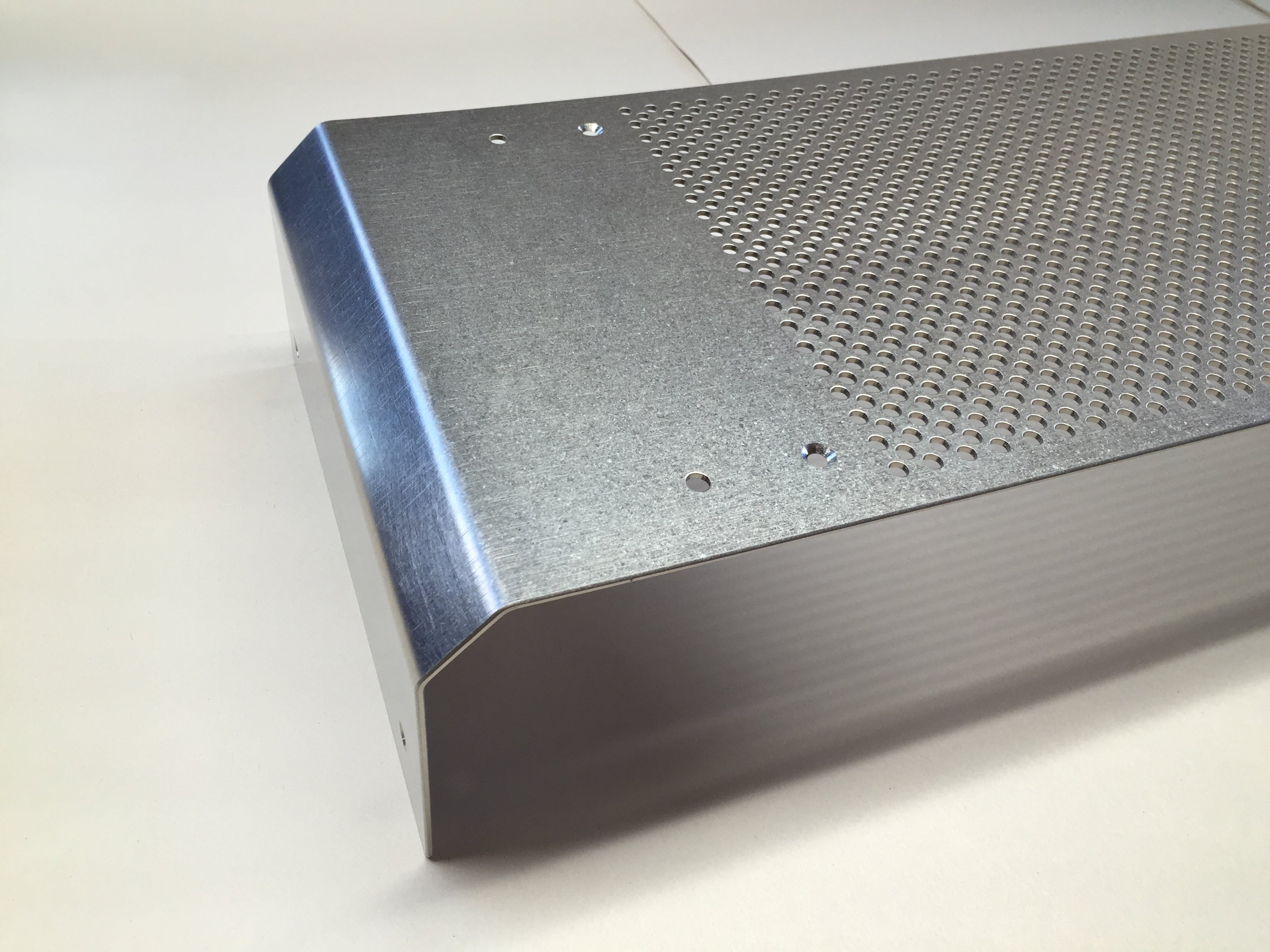

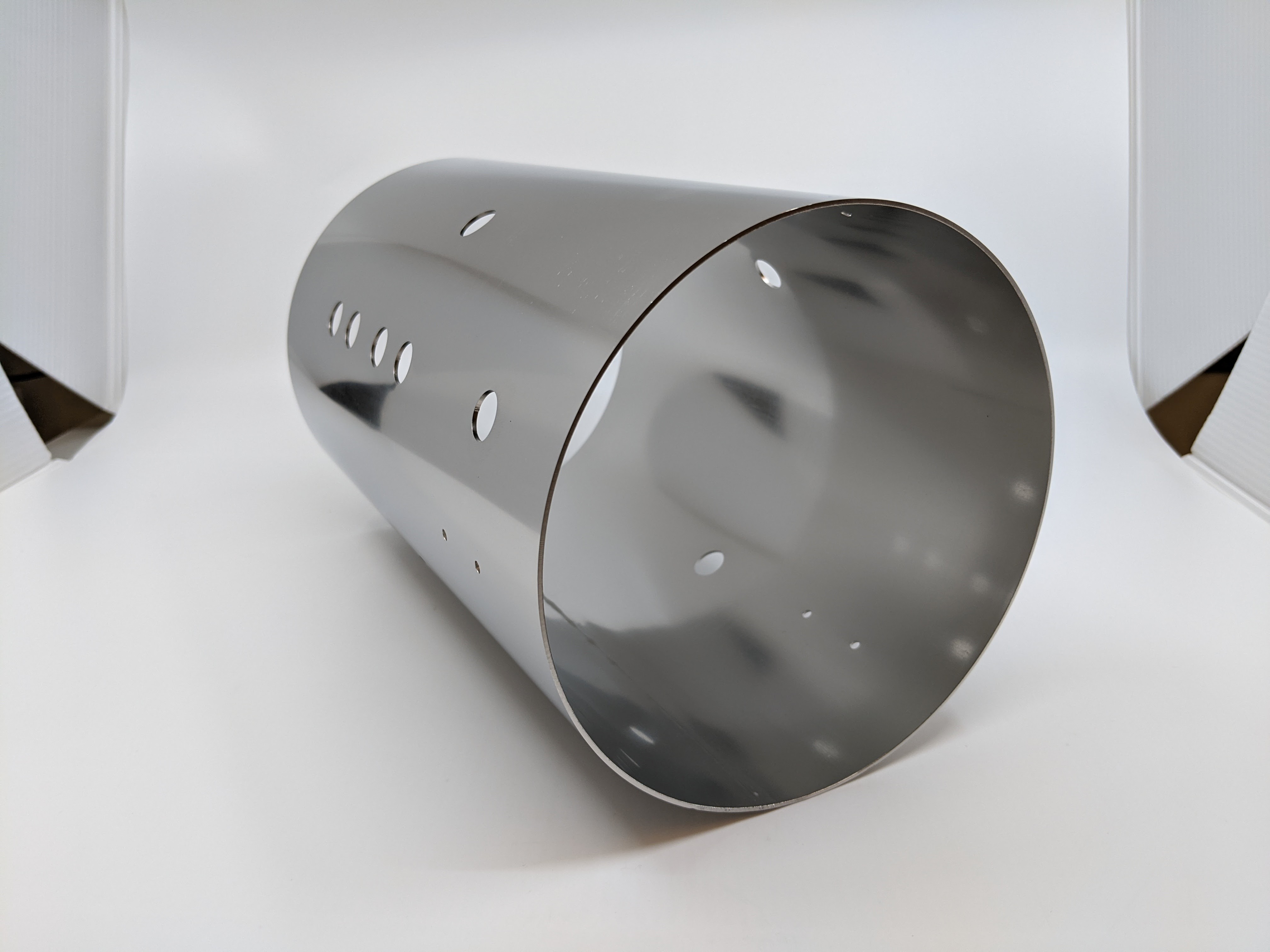

Most magnetic shields require cutting flat blanks into unique shapes with tight tolerances. Our magnetic shield fabrication and prototyping processes use wire EDM, waterjet and laser cutting as well as foil slitting and sheet/plate shearing to prepare your blanks. To create your 3D shield, rolling, stamping, bending, welding, spinning, hydro-forming, and deep-draw forming are used. CNC machining is available for solid, thick-wall shields made from our stock MuMetal® round bar and thick plate. Additional polishing, plating, coating, or painting are available. The most critical and final process step of fabrication is final annealing (heat treating); then testing in our ISO 9001 certified Quality Assurance Lab using one of our Helmholtz coils.

Perfection Annealing

After fabricating your magnetic shield, Perfection Annealing is required to re-crystallize the material which produces the highest permeability shielding and improves shielding efficiency.

Prototyping

Using our stock MuMetal®, Co-NETIC® AA, CRYO-NETIC®, Co-NETIC® B, or NETIC® raw materials, we quickly prototype your shield. As experts in low-frequency electro-magnetic interference, we have learned hands-on prototyping is the most practical method to prove validity of simulations and calculations. Magnetic Shield Corporation’s model shop and prototype tooling help customers prove their design and meet their specification with minimal investment.

Request a Quote

If you require custom magnetic shield fabrication and prototyping services, please Request a Fabrication Quote and submit a drawing or sketch. Upon receiving your information, our Engineering & Technical Services team will estimate shielding attenuation, calculate material type and thickness, sketch mechanical construction, and recommend our findings. A quotation will be provided for parts, prototypes, and specialty tooling as needed.

For testing and experimentation with our materials, purchase one of our Evaluation Lab Kits.