As a technology leader since 1941, Magnetic Shield Corporation has helped scientists, inventors, educators and students by providing engineering support, low field testing, simulation, and CAD design services. We work within the research community supporting US National Laboratories, international research organizations, universities, medical research facilities, US Department of Energy, NASA, and private space exploration companies.

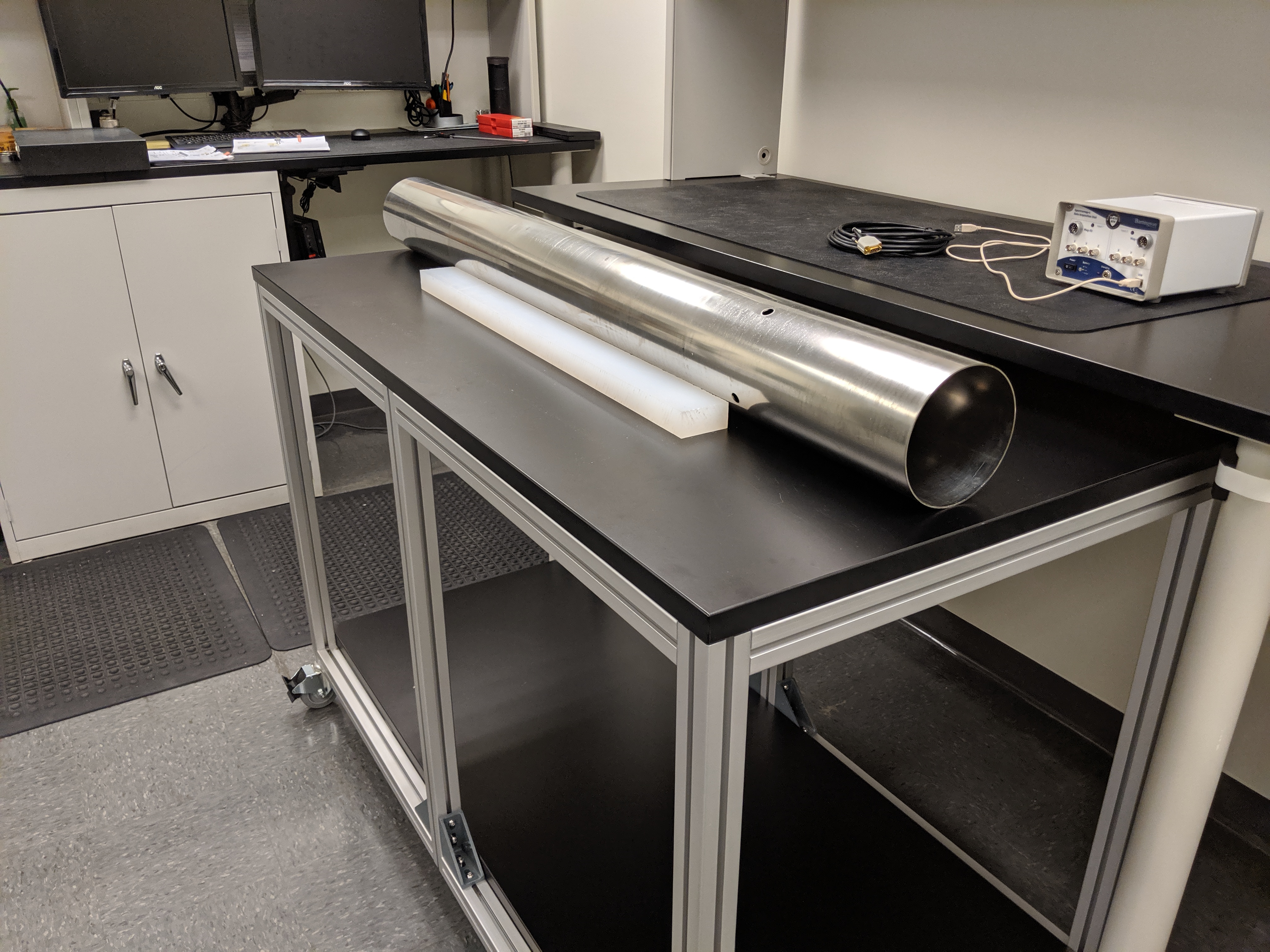

In addition to technical advice, we provide a hands-on approach to design and testing; fabricating one-off shields and prototypes for evaluation of shielding efficiency in your design. We have a full range of stock shielding alloys and can accommodate any size research project.

Why work with Magnetic Shield Corporation? Because our shielding alloys are field proven in the research community; and, with our decades of hands-on experience, you can be certain you are not wasting valuable time or funding. For additional help, network with Universities on Facebook, or contact our Engineering & Technical Services team with any specific questions.

Measuring Magnetic Fields

How do you "see" magnetic fields? By using a Gauss Meter, the electromagnetic source field strength is measured in "Gauss", and output into numeric values and scales. An example on YouTube shows Gauss readings before and after shielding an electrical panel with our MuMETAL® alloy. For this type of field measurement, we offer a cost effective, handheld, single-axis AC magnetic field meter to provide quick & reliable measurements of electromagnetic field (EMF) radiation generated by external sources like electrical panels, electrical wiring, power lines, audio/visual equipment, motors and other devices. No probe is required - just hold the Gaussmeter in the affected area. Then measure the same after shielding with MuMETAL®, Co-NETIC® AA, Co-NETIC® B, or NETIC® shielding alloys. For testing and experimentation with our shielding alloys, use one of our "hands-on" evaluation kits. Purchase an Evaluation Lab Kit and Gaussmeter and receive 10% discount on your order.

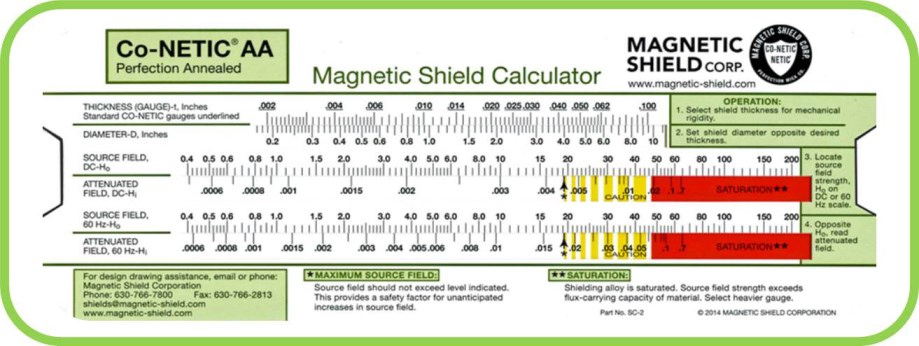

Slide-Rule Calculator

Formulas may be used to determine which materials and thicknesses will provide the most efficient shielding. The source (interfering) field known as HO is measured in Gauss. Knowing HO, and estimating the approximate size of your shield, shield thickness can be determined mathematically. Certain characteristics of shielding alloys are theoretically constant such as permeability µ (Mu), saturation induction, and flux density (B).

Our Slide-Rule Calculator mathematically determines thickness of Co-NETIC® AA Perfection Annealed alloy required to attenuate unwanted fields. The slide-rule scale is developed for cylindrical shaped shields (the most common shape used for absorbing magnetic field lines); therefore it is necessary to further evaluate using our "hands-on" developmental Lab Kits to provide real evidence of success. Note: A Slide Rule Calculator is included with every Evaluation Lab Kit purchased.

Additional Resources

Generally, these additional resources will provide a working understanding of magnetic shielding. However, feel free to email us if you have any specific application questions. Click on our brochures below for in-depth product specifications.

Product Literature and Specifications

Educational Tools

Each day we receive unique inquiries from students, inventors, scientists, and engineers - many with limited knowledge of how magnetic shielding materials can be used to avoid unwanted interference. Whether you want to study shielding theory, learn shielding calculations, or test the differences between our shielding alloys, we can help.

For classroom and lab study, our University Lab Kit offers a tool for educators to involve students and small groups in "hands-on" discussion.

For individual "hands-on" evaluation, testing and prototyping, our Evaluation Lab Kits offer larger samples of fully annealed material and a full binder of technical information.

Shielding Materials

Shielding efficiency is a result of material composition, specific gravity, thickness, grain structure within the alloy, and hardness. Depending on strength of the unwanted field (HO) and the amount of field Attenuation you need, one of our five alloy types may be selected.

Final Anneal

After fabricating any magnetic shield, final annealing is generally required to increase grain structure, which improves shielding efficiency. Final anneal is a critical process step and extra care must be taken to avoid dropping or denting as shock may weaken an annealed shield's grain structure. When magnetic shields are manufactured by Magnetic Shield Corporation they are Perfection Annealed (fully annealed in a controlled hydrogen atmosphere) to Magnetic Shield Corporation's exacting standards. Optimum magnetic properties are obtained by annealing at a temperature of 1950-2050°F [about 1120°C], and cooling at a consistent rate which is critical to maintaining grain structure and part dimensions. Final anneal specification varies by type of shielding alloy.

B-H Curve

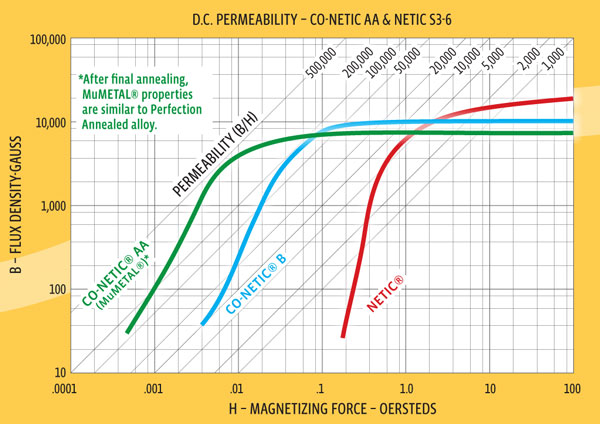

Over several decades, Magnetic Shield Corporation has performed hundreds of laboratory tests and calculated thousands of shielding equations - all in an effort to continually validate the theoretical application of magnetic interference control in both AC and DC applications, and to aid engineers in shield design. Theory behind the B-H curve is well documented, and it remains an effective reference tool. By use of the B-H curve, our shielding alloys MuMETAL®, Co-NETIC® AA, Co-NETIC® B and NETIC® have been developed and refined to offer the most effective shielding characteristics for a variety of applications and markets. The B-H curve (below) depicts our materials' capabilities to attenuate and absorb a wide range of magnetic fields. For a spreadsheet version of our BH curve please contact us.

When it comes to magnetic shielding, remember:

"Theory is one thing, practicality is another, evaluation is everything."